Deepwater Oil Spill - Pressure Tutorial - and Open Thread

Posted by Euan Mearns on June 6, 2010 - 9:00am in The Oil Drum: Europe

Please transfer discussion to http://www.theoildrum.com/node/6572.

There has been much debate about pressure in relation to the Macondo blow out and I thought it might be helpful to explain the origins of sub-surface pressure differentials in as simple terms as possible.

Note that I am a geologist, not an engineer. The diagrams are intended to be cartoons to illustrate simple concepts.

(a) Basic concepts

Pressure increases with depth in the sub-surface proportinal to the density of material. The lowest density material encountered is normally gas which has the shalowest pressure gradient, followed by oil, water and then rock. Normally pressured water is called the hydrostatic pressure gradient. But in the sub-surface, the presence of regional rock seals may produce over pressure in water caused by rock pressing on water (see example d). The rock pressure gradient is referred to as the lithostatic pressure gradient.

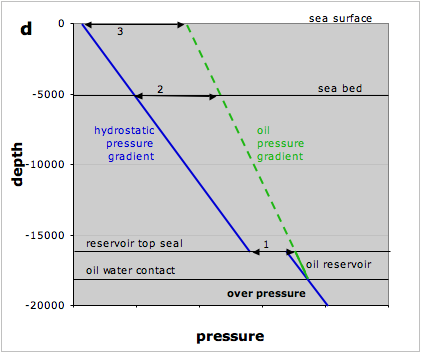

(b) Common configuration in reservoir

In an oil / gas reservoir the oil essentially floats on water and the gas floats on oil. The top seal prevents the oil and gas escaping giving rise to the pressure configuration as shown. The "pressure kick" at the top seal (1) is contained when drilling by the drilling mud.

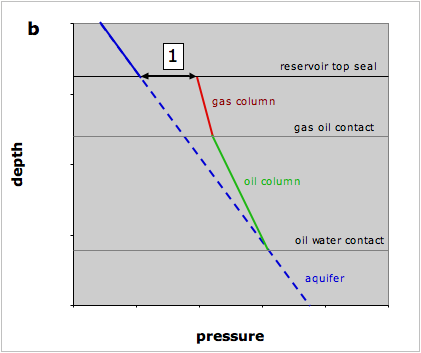

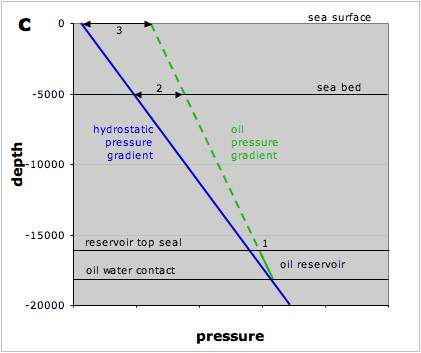

(c) Common configuration in production tubing

If oil (± gas) are allowed to enter production tubing then a column of oil ± gas may exist all the way to the surface. This long column of low density material creates large positive pressure differentials that need to be contained by the production infrastructure. Note how the pressure difference grows up the well.

Pressure difference on the sea bed (2) is lower than on the sea surface (3). In the case of Macondo, the 5000 ft column of water exerts some useful pressure, limiting the flow of oil from the well.

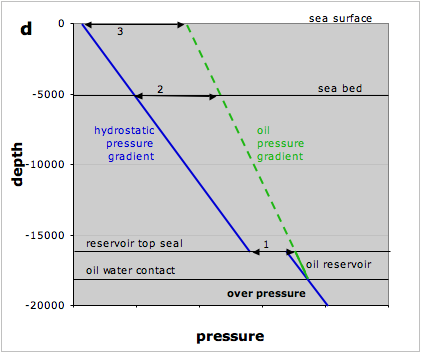

(d) Over pressure

Deep reservoirs such as Macondo are often over pressured. That means that regional rock seals prevent subsurface water escaping. The rocks above can then exert some pressure on the water.

Note how over pressure can create a much larger pressure differential at the top seal. These are the large pressure kicks that are of great concern to drillers in this type of environment. Note how over pressure gets transmitted to surface through oil and gas in production tubing.

Prof. Goose's comment:

A continued humble and sincere thank you to all who have donated thus far. It will help us pay for the fourth server we brought online to accommodate the increased traffic. (See point 3 below.)

1. The Oil Drum is a pretty special place. We strive to maintain a high signal to noise ratio in our comment threads. Short, unengaging comments, or comments that are off topic, are likely to be deleted without notice. (to be clear--engaging, on point humor and levity, more than welcome.)

We are trying to perform a service to the public here to coordinate smart people who know their stuff with other people who want to learn about what's going on. Promotion of that ideal will be the criteria by which we make our decisions about what stays and what goes.

Flame wars, polemic exchanges, and other content deleterious to the community will be removed, either by an editor or by the community through its moderation process.

2. If you see a problematic comment USE THE COMMENT MODERATION SYSTEM--see the "Flag as inappropriate" and (?) beside it? Learn more there. If you see comments that are questionable after you've done that (that aren't being removed), let us know at the eds email address.

It is up to this community to enforce the norms we have established here (a high signal to noise ratio), keep. it. up.

Our guide to commenting at TOD can be found here: http://www.theoildrum.com/special/guidelines . Please check it out if you are unfamiliar with it, but it is essentially 1) citations welcome (if not necessary), 2) be kind to others, and 3) be nice to the furniture.

3. We have gotten a lot of queries whether this bump in traffic is adding costs to keep the site functioning. Truth is, yes, we are incurring added expenses from these events. It is also true that we try not to beg from you very often as we are not the types to bother you with constant queries.

That being said, if you are inclined to help out, your support is always welcome and very much appreciated. To those who have already given, thank you very much.

You can find the donate button in the top left hand corner of the main page.

4. If you have come here to vet your plan to kill the well, understand that you will be queried on whether or not you have read the other 10 previous comment threads and all the myriad plans that have already been run by the kind folks in this room; if you have actually read all 10 comment threads and still think your plan has legs, well, then maybe yours really is the one that will save the Gulf of Mexico.

This is not to say that well considered questions about current attempts and modifications to those attempts are not welcome; they are. But try to place them in context and in what's actually going on, as opposed to your MacGyver dream solution where you have a 10 megaton bomb, an ice pick, and Commander Spock at your side.

5. Also, if you're looking for live chat to talk about the ROV/LMRP video, etc., and are IRC capable, go to freenode, the channel is #theoildrum

(google MIRC and download it; Hit the lightening bolt and fill in your info; select the server as "freenode" (it is in the server list), hit connect; when connected type /join #theoildrum)

or you can get there just via a browser: http://webchat.freenode.net / Just enter a nickname and #theoildrum in the boxes; then when connected type /join #theoildrum)

6. Do not be afraid to go back and read the last couple of open threads yesterday and today before you start on this thread. They are really good, and will likely catch you up if you have been out of the loop for a while. We shut down threads when we get to 300-400 comments, as it's really unmanageable. Lots of good stuff in there though.

Morning Gail, you must be up early today. Readers may note that TOD Europe is running an ad called "Blame Obama". We have no control over the ads posted on the site.

Good Morning,

Physically, 100 gallons of oil displacement @ 5,000ft below Sea level becomes 150 +/- gallons at the surface. What I'm getting at is a realistic view of the estimated size of the spew at the sea bed, compressed, in comparison to the claimed capture rate of Oil measured at the surface.

Sorry, the Coffee is good today. : )

I'm not the person to answer a question on compressibility - I don't think it will be very compressible. But it does shrink when cooled - so the surface volume when cold will be less than the reservoir volume when hot.

A good answer Euan. Though folks seldom qualify the numbers when oil/NG volumes are stated they are typically STP...standard pressure and temperature. Essentially surface conditions. Oil and water do have a compressibility and thermal expansion component but is relatively small and doesn't amount to much. OTOH, NG is obviously very compressible and the volume expands many times over when going from reservoir pressure to STP.

I'll take advantage of Euan's post and expand on it with regards to recent question regarding the drilling risks associated with the relief wells. This is a matter I have experience with first hand in recent years. Prior to drilling a DW well there's needs to be an estimate of the pressure gradients Euan has described. If there is not a well close to the new location the pressure gradient model (PGM) has to be estimated from the seismic data. Compared to a PGM generated from a nearby well, a seismic derived PGM is rather crude but it's all we have to work with sometimes. This is why the PGM is modified while drilling. This was one of my tasks in a former life: well site pore pressure analyst (PPA). As the well is drilling a variety of rock property data as acquired by electronic sensors just behind the drill bit: logging while drilling (LWD). This data is transmitted continuously back to the surface. As simple as it may sound the data is essentially transmitted like a telegraph signal. Pulses are generated in the LWD tool and transmitted to the surface via the mud column. On the rig the LWD data is decoded and ready to use. Though I can't predict the PGM ahead of the bit I can determine how close it's matching the pre-drill model. Even when there isn't a dramatic change in rock pressure there are limits to the range of mud weights used to drill a hole. That's why we see so many csg sets in the RW's. Too light a MW and the well flows. Too high a MW and you fracture the rocks and can easily lose the hole.

With the PGM gained from drilling the blow out well they have a pretty good handle on the MW's and csg points needed in the RW. But the actual intersect event may still be very tricky. I haven't seen details of the PGM from the blow out well so I can only speculate. Consider drilling the same rocks at this location but assume the is no oil/NG in the reservoir. The MW needed to stop the flow of water out of the reservoir might be 14.0 ppg. The rock might be fracture at a MW of 15.0 ppg. That's a fairly wide margin and should not be a problem. But now put a 400' tall column of oil/NG in the reservoir. One big reason the DW plays have attracted so much attention is the very tall hydrocarbon columns encountered out there. This tall hydr. column will raise the pressure in the reservoir to the point that a 14.7 ppg MW is needed to contain it. Now you have only a 0.3 ppg margin before rock failure. And this is where DW drilling offers a challenge seldom seen elsewhere: the ECD factor. ECD is the effective circulating density. The mud might weigh 14.7 ppg but when the mud pumps are running the effective mud weight (ECD) at the bottom of the hole maybe several tenths of a ppg higher. So in order to not fracture the rocks you might pump a 14.5 ppg (with an ECD of 14.9 ppg...less than the 15.0 ppg that would fracture the rocks). But when you turn the pumps off to add drill pipe or pull out of the hole the ECD drops to 14.5 ppg....less than the 14.7 ppg needed to keep the reservoir from flowing oil/NG to the surface. I've seen operators drill into such a situation: you can't raise the MW to stop the well from kicking, less you fracture the rocks, and you can't turn the pumps off to pull out of the hole because the well will kick. I've seen operators pump cement down such a well to kill it and then plug and abandon the well.

This example highlights why watching mud returns is such a critical safety protocol. You're drilling and everything is fine: the well isn't trying to kick and you're not fracturing the rocks. But then you turn the pumps off to add a section of drill pipe and now the ECD isn't sufficient to keep the well from kicking. And how do you know the reservoir is flowing into the hole? Even with the mud pumps off the mud continues to flow out as it's being pushed upwards by the oil/NG. This is why checking mud returns is so critical. Even when there isn't a need to stop the mud pumps you periodically do it anyway to see how close you are to that tipping point. This may be one reason the RW effort will seem to turn aggravatingly slow as the intersect is approached. It may be a very close balance of ECD needed and could take a number of days to fine tune it before the final hole is cut. No doubt we'll be discussing this in the next 6 or 8 weeks.

Rockman, do you mind expanding on what happens if you fracture the rocks?

I have visions of the mud draining away so you need to pump more mud to keep the pressure up until you have no mud left then... kablooey! But I don't know if this is realistic.

aardy -- several bad outcomes. The least serious is that you pump mud (actually the liquid portion of the mud) into a productive reservoir and reduce or completely destroy its production capabilities. Next worse is the sucking action caused by this lost circulation into a porous rock: the drill pipe can get stuck (differential sticking) and you might have to leave some of it in hole and then drill a side track. Next you can actually cause the rocks to break apart and the hole will collapse. More lost drill pipe and a side track. The worse case is when you have such lost circulation in one zone while another zone is kicking you. You lighten mud weight to stop the LC but that makes the kick worse. The primary purpose of the multiple csg runs is to minimize this range of too light/heavy a MW.

Probably the scariest well I've been on in the GOM DW was about 6 years ago. They had set csg and were drilling ahead at 22,000'. And then they started to loss circ. They weren't sure where but it might have been at the previous csg shoe. They lost 60,000 bbls of OBM while drilling. No mud ever returned to the surface. So no mud log telling them if they had drilled oil/NG, no LWD to estimate pore pressure, no mud parameters to tell if the MW was being cut by oil, NG or water. And most importantly, no way to tell if the well was kicking. They put very heavy drill mud on the outside of the drill pipe but that would have not stopped a blow out coming up the inside of the DP. Took me 6 days to log that 2,500' of open hole. I ran pressure logs in the wet reservoir they cut: 19,000 psi bottom hole pressure. They were probably very lucky they didn't find oil/NG in that sand: a blow out could have easily happened. How scary was it? Some of the hands were sleeping in the escape capsules when they were off tower. And this insane risk was taken by a well known and very experience operator. Needless to say someone very high up in the company was willing to risk the 130 souls onboard that drillship to get this well down. Equally needless to point out: that person never set foot on that rig. We just finished the job, went home, cashed our pay checks and then tried to forget about it.

Rockman: "And this insane risk was taken by a well known and very experience operator. Needless to say someone very high up in the company was willing to risk the 130 souls onboard that drillship to get this well down."

WHY?

Exactly my question, but I'll do an uneducated guess: Were the rock conditions known to have the risk that you described here beforehand and the company decided to press ahead anyway?

sty -- If the assumption that the mud was being lost at the csg shoe is correct then it had nothing to do with rock properties. Just a bad cmt job...again.

EL -- Just a guess but I've always assumed this project was a career maker/breaker. BTW...I never use the word insane lightly.

Unbelievable. I expect this is one reason why you no longer do DW.

It is a complete failure of regulation to allow anything of this sort to occur. This type of profit-at-any-risk thinking made a catastrophe like the one we are in now inevitable, not as Tony would like you to believe, a "one in a million" event.

I mentioned a while back why I don't do offshore anymore. My 9 yo daughter had never perceived me being in any danger out there and we let her hang on to that. But then her best friend's

dad was killed in an oil patch accident. Another human error incident...his. So with tears in her eyes she begged me to not go offshore anymore. So that was an easy call. Oddly, perhaps because she's been to onshore drill sites, she wasn't worried about me as long as I stayed on the bank.

I never mention the names of former clients especially if I'm not saying nice things. But let's say a little karma is at work out in the GOM today.

Best. Post. Ever.

Don't I recall that this well hit a fracture section that required a bunch of drill pipe to be left in the hole and a side track to be bored?

Don't know what they hit but they did get stuck and had to drill a sidetrack. It is the sidetrack that blew out.

I don't have the figures in hand, but as I recall that sidetrack was at around 5,000 feet below the mudline, and over 5000 feet above the payzone. If the blowout got though that much rock, then we've got bigger problems than we've yet seen.

Fracture and lost circulation at top of reservoir 18260

ROCKMAN

Yesterday Robert Rapier stated in his post on the future of BP that he now believes we have exceeded the depths at which we can drill and extract oil safely. In the light of your description of the extreme difficulty of such drilling, I would be interested to know your feeling about this issue, if you would be willing to comment.

Drilling 500 feet blind let alone 2,500ft in this type of environment is insanity and frankly it is difficult to believe any prudent operator would do this. In fairness, I have seen some pretty stupid decisions made which I have had to clean up.

There is an old oilfield adage which I hold dear,

"Courage is proportional to the square of the distance away from the wellbore."

Sometimes the best answer is simply "NO!". I am more than content to pull to shoe and circulate while they find my replacement.

RM -- wow that's scary

if you have a few free minutes ....appreciate it if you can post a few more details on this particular well.....always a learning experience hearing about such wells from the geologists POV

thanks much

The common thread I can see in all of these incidents (including DWH) is that people in charge of (and compensated based upon) the drill rig's production are also tasked with maintaining its safe operation.

In other high-risk operating environments (and I have worked in several) from pipelines, to refineries, chemical plants, nuclear plants, electrical facilities, etc., these two conflicting tasks are seperated and handled by completely separate staffs and even divisions. The safety teams are completely empowered to halt operations unless they are satisfied that safe operations are either possible, or are occuring. If a production manager gets shut down by the safety personnel, that is a black mark on their record, giving them incentive to avoid it. Likewise, there is no disincentive to the safety teams to shut down a risky or dangerous operation, as that is seen as preventing potentially company threatening losses. Losses such as the one BP is facing right now.

Some notes for the record:

BP- all is well says CEO Sir John Brown, oops, got caught lying to a judge, yer outta here says the Board of Directors, valiantly trying to cover their butts. But governments and media continue to base plans for the future on the BP statistical revue. Meanwhile 12 BP traders indicted within the Natural Gas Liquids department for LPG futures manipulation.

Mr. Browne had bought Amoco, an ailing corporation, in 1998 as part of his inspired dash for growth. Over the previous seven years, as BP's oil reserves declined in Alaska and the North Sea, Mr. Browne talked about his plan for a succession of bold acquisitions and championing of risk to save BP from gradual extinction. By 2005, Mr. Browne's ambition to transform BP into a powerful challenger to Exxon itself seemed to be materializing.

To cut costs, Mr. Browne had not replaced hundreds of engineers who had left and committed BP to rely more on sub-contractors. Brilliantly, he had simultaneously rebranded BP with the sunburst logo as "Beyond Petroleum," an environmentally friendly corporation blessed by a green destiny. The explosion at Texas City endangered that dream.

In the aftermath of the explosion, a blame game erupted. BP was the biggest oil producer in America and the most successful operator in the Gulf of Mexico, and its reputation was at risk. The company was accused by the U.S. Chemical Safety Board, an independent federal agency, of cutting the costs for safety and maintenance to increase profits. His response was rapid.

Amoco's engineers and executives, the British executive told his fellow BP directors, were themselves responsible for negligence and "cultural misunderstanding." Former employees of Amoco, which was now part of BP, rejected any suggestion of their personal culpability.

As the head of BP's production during the Texas City saga, Tony Hayward, Mr. Browne's successor, has already visited the Houston command centers monitoring the explosion at the Mocando site in the Gulf of Mexico. As the oil spill now hits the Louisiana coast, Mr. Hayward may be mindful of his predecessor's eventual failure to limit the repercussions of successive accidents.

I don't think that is close at all.

Compressibility of oil is about .007 percent per atmosphere.

http://www.engineering.uiowa.edu/~cfd/pdfs/tables/1-42B.pdf

5000 ft down = 160 atm.

The change in volume will be 0.007 x 160 percent or 1.12 percent. 100 gallons at the ocean floor will be 101 gallons on the surface.

The oil is not all that compressible, but the solubility of gas in the oil does vary greatly with pressure, and thus depth. And if I understand it right, once the gas has come out of solution the oil volume shrinks, not nearly as much as the volume of gas exsolved, but significantly - 30-40% maybe, from reservoir conditions. So a barrel of oil at the surface might represent 1.4 barrels at the bottom of the well and somewhere in between at the sea floor.

Agreed. What got me to post was the OP claim that compressibility of oil meant that 100 barrels subsurface expands to 150 barrels at the surface.

Totally baloney of course.

Excuse Me Mr speaks to animals Sir, I plead ignorance in this case, not being a physicist, but. Temp change at that depth certainly must come into play also along with barometric pressure. I can hardly believe that 100 gals of oil 5000' +/- below at the well is the equivalent of 101 barrels at the surface. Are You affiliated with BP by any chance?

"..I plead ignorance in this case, not being a physicist.."

You can say that twice.

I am a physicist. You are ignorant in this case, and the Speaker is right. Liquids really, really, *really* don't like to be compressed.

gosh is that why oil is used in hydraulic systems? :oO

I am also a physicist. The volumetric coefficient of thermal expansion for oil is on the order of 0.0007/(degree Kelvin). The reservoir temperature was reported to be 140 Fahrenheit, or about 333 K. The change in temperature of the oil as it flows to the wellhead is unknown to me, but I imagine that frictional in the flow heats the oil somewhat so that it would be hotter at the wellhead. Thermal expansion also increases the volume. If the heating is modest, say to 343 K, then I find a factor of 1.007, or about a 1% effect which should be added to the 1% effect already, and correctly estimated by Speaker to Animals. So maybe 100 bbl at the reservoir becomes about 102 bbl at the wellhead instead of 101.

http://www.engineeringtoolbox.com/volumetric-temperature-expansion-d_315...

We are comparing surface vs. well exit volume.

So the temperature change volume correction is negative, not positive. And we are still basically at 100 barrels +/- 2%.

The arithmetic is left as a homework problem.

Glenmore, I know what you mean but I can't help myself. It is true that the amount of gas dissolved in a given mass of oil increases directly with the partial pressure of the gas, if the temperature is constant. This is Henry's Law. But the solubility of the gas does not vary at all. It is independent of the pressure, although it decreases with increasing temperature. So, five times the pressure, five times the amount of gas dissolved in a given mass of oil, if the temperature doesn't change.

I was surprised to find that American Petroleum Refining by Bell (3rd ed, 1945) does not even mention solubilities.

I would like to know more about the change in volume of oil as the amount of gas dissolved in it changes. I am dubious. This does not happen with any liquid I know of, either at all or to any extent worth noticing. For example, the volume of beer is not affected by the amount of CO2 it has absorbed. You could check it out.

So TOD's subsections (TOD: Europe, OZ, etc) are separated from the 501 (c)(3) of TOD main?

Euan,

This is a good topic for a tutorial post, thanks.

The first thing that occurred to me when I saw the diagram was that the pressure gradient should steepen below the seabed, or that there should be another line showing pressure due to rock density.

The rock is denser than the water and its steeper pressure slope could illustrate the pressure difference that was the motive force of this well kick.

Great information here. Thanks for sharing.

Hayward has just concluded an interview on BBC

11:07 GMT, Sunday, 6 June 2010

"Speaking on the Andrew Marr Show, Mr Hayward said: "As we speak, the containment cap is producing around 10,000 barrels of oil a day to the surface." Asked what amount of the estimate that represented, the BP chief executive said it was expected to be "the majority, probably the vast majority" of the oil gushing out."

here is a screen shot at 12:47 GMT Sunday, 6 June 2010 http://i47.tinypic.com/sb288g.jpg

and here is the live stream http://bit.ly/cRYuHX

I am willing to bet that either "10,000" barrels or the "vast majority" are "vast exaggerations".

Well they told him the leak was 16000 and if they are getting 10000, that must be the "vast majority". He hasn't seen any pictures recently and nobody has re-estimated the flow rate.

I just checked the ROV cam, and there is a good bit of oil escaping from under the cap. IMO, "vast majority" is BP BS. I'd be surprised if they have the leak down to the 5K BBL/D they originally claimed.

June 6, 2010 at 13:01 CDT the flow does not look reduced.

When Top Hat 4 was installed on Thursday, the fins were visible and occasionally a patch of flow would thin enough to see the yellow side. I think BP is only collecting the flow that used to pass through the open ports without reducing the amount leaking from under the seal.

It's been clearly stated that you can't look at a feed and determine anything of value. This cap was taken 1 AM Sunday and the view from each ROV looks vastly different, but they are all pictures of the same thing at the same time. The thin patches showing the yellow in the background are currently still visible from Herc 14, color temperature of the lights and camera settings on Herc 6 is why you can't see it in your cap.

I do think it's kinda disturbing that the paint has been blasted off the fins, and they appear to be rusting.

I've been looking at the feed on http://mfile.akamai.com/97892/live/reflector:46245.asx.

There's been a huge improvement in the amount of oil being captured over the last 24 hours. Yesterday the lower fins of the dome were mostly obscured by billowing oil. Now they remain clearly visible.

Somebody needs to get a handle on the numbers. Until we get a flow rate any claim made by BP will need an error associated with it, and are essentially meaningless. Though BP may be acquiring some oil, I don't see much difference in the feeds.

Tony Hayward is a geologist. "Vast majority" is not SI (International System of Units).

I think we need to assume that US coastguard is monitoring / auditing situation. And I think folks need to be able to recognise good news when it happens.

Note that pressure differential at surface is higher than at seabed, hence surface flow rates may be higher. Off setting this is the possibility that the cap helps choke off some flow.

Flow rate via the RITT was pretty erratic...is flow thru this system likely to be more stable?

At steady state, the flow of total material by mass entering the main flow of the pipe has to equal the flow of material by mass exiting the pipe. That is a mass balance law or simply conservation of matter. If this does not hold something is leaking between the ends.

I thought to bring this up because it almost seems too fundamental not to associate it with what is happening.

Maybe 'vast majority' translates into 'parent's speak' as: "We'll get there when we get there."

Coast Guard has no competence to audit topside flow.

Exactly what I was thinking. All I see in the live feeds is a bunch of oil billowing out and it looks terrible. I understand that it might not be nearly as bad as it looks, though. I hope it is.

I was thinking last night that perhaps another alternative to my earlier guess that this would end deep-water drilling off U.S. shores is that instead it might give rise to a whole new technology that can be used by BP and others to ensure to the public that deep-water drilling is, in fact, safe.

For example--and I'm just speculating, here--can BP now, I dunno, patent the oil containment system that they've developed and sell it to other oil companies to have on hand in case of a deep water blowout?

I know that isn't going to happen because probably the industry doesn't work that way, but I use it to illustrate a point. Is there an opportunity now for some manufacturers to come up with a whole new line of emergency blowout containment systems for deep water environments?

Then the companies could say, see, we are prepared if this happens again. All we got to do is pull ol' Number Eight from our warehouse, fly it in, fit it on top of the leak, and you only had 10,000 barrels total leaked while we drilled the relief well.

I think maybe a skeptical public would mostly buy this argument and put up less of a fight against local oil exploration, especially if the only alternative would be that they would have to reduce their consumption of petroleum products (i.e., buy smaller cars, drive fewer miles, use less plastics, investigate alternative energy sources, and do all the things that we should be doing to confront peak oil but don't because (editorializing starts) we're lazy, cheap, spoiled, and stupid).

I realize this is likely not a new concept at TOD but a bar graph showing anticipated impact of every SUV, or under-utilized F-250 downsized to a more practical vehicle might be very effective in getting these points across. How many barrels saved vs. today's bad habits and narcissistic, reptilian choices.

Note: long time TOD reader, but crappy memory

What about the people who need SUVs? I have a Grand Cheorkee which is the smallest vehicle that has the towing capacity to pull my 24' camping trailer. If I downsized to a more 'practical' vehicle then I can no longer use the trailer.

Another issue is that at 1230 hours, 16 Jun - I will become a father of twins. (One boy and one girl.) A test loading of the vehicle* has demonstrated it is able to fit two adults, two infant car seats, a double stroller, the necessary bag of baby gear - and not much else. At this point I am kind of wishing I had a Suburban.

Now - I use a Toyota as my commuting (I live in Los Angeles where it seems you have a choice of driving an hour each way to and from work or being unemployed) leaving the Jeep for my wife so it gets fairly low mileage.

What kind of bothers me here is that I get the impression that you think that there is something wrong with me for determining my needs than getting the vehicle that best fits those needs.

*I deal with stress by over-preparing and over planning.

Your analysis is adequate as far as it goes -- you drew a line around your life and needs.

If you draw it a bit bigger, you question why gas is so cheap, and whether it wouldn't make more sense to rent a truck when you need it, or forgo the camping trailer.

Did you get the hemi? A diesel would get better mileage and pull better. A pity you can't get such in a small SUV or pickup.

I miss my Suburban when the whole family goes anywhere. Now we rent a minivan a couple of times a year. It's easily paid for by not spending $100 per fill-up on the Sub, but it's a hassle.

The real hassle will come when there isn't enough oil to go around, and those who still have decent jobs will feel guilty (or endangered) for flaunting their consumption.

Paleocon:

I think Activated05b will see. Life's hard. And he's young. Wait till the Water Wars hit LA. He will measure out his life with coffee spoons. [sorry, Mr. Elliot]

You feel you "need" an SUV to pull that 24' camper that you also "need"?

You still feel you not only need stuff like this, but you want even bigger fuel guzzling stuff, even after the information here and the current disaster?

I think there is a lot wrong when we as a people can't tell the difference between a NEED and a WANT.

What kind of bothers me is that I get the impression you don't understand the difference between "need" and "want." A giant travel trailer + tow vehicle...is a "want" and not a "need."

That's the only way a free world can live, fortunately or unfortunately. People should be able to freely fulfill their wants as long as they are able to afford them. Anything else is a command system with rationing and no one will like living that way including you.

That said, the system will work just fine - gas is already relatively more expensive than it was 10 or 20 years ago and it will continue becoming more so naturally limiting what people can do, forcing different better choices on them.

el_cheburako: Instead of peacefully obeying the laws of supply and demand, sometimes people choose violence or war. Perhaps, the Owens Valley on an enlarged scale? For a number of years, LAPD had to maintain a substation just outside Mammoth Lakes, CA to keep the violence suppressed and the water flowing from the Owens River to LA for the Chandler family's real estate development in the San Fernando Valley. Today, don't go into a bar in Long Valley on a Saturday night and say: "Hey, I'm from LA." You may become a floater.

"People should be able to freely fulfill their wants as long as they are able to afford them"

This is anarchy, not society. People should not be able to freely do whatever the hell they want with no regard to the impacts of those choices on other individuals, society, and the world as a whole. What you state is by no means a universal tenant of humanity subscribed to by all citizens, even in "free societies."

So people should just be free do whatever they can pay for and to hell with the group?

As much as I would not like to live in China, what do you think conditions would be like there now if the government had not commanded fewer children? Which is worse; the government limiting you to one child or millions starving?

If the market is working, and gas is relatively more expensive than 20 yrs ago, why have so many Americans increased their home size and fuel consumption so much in the past 20 yrs?

Do we have enough fuel to wait for them to learn slowly? very slowly?

What will the system do about the lower income people who will not be able to afford to go to work or heat their homes because someone with more money made the free choice to waste fuel on non-essentials?

El Che

Have you ever heard of "Tragedy of the Commons"?

Check it out please:

http://en.wikipedia.org/wiki/Tragedy_of_the_commons

Er, I meant "I hope the oil leakage ISN'T as bad as it looks."

When they removed the riser they increased the flow by some 20%. We need to remind the media that anything less than 20% containment represents a failure of this strategy (and a net gain in the flow of oil).

Yep. Capturing 10,000 barrels over a period of days ,or even bpd, on a leak that was previously estimated at 12 to 19k per day does not amount to a success if the current rate is twice the original. No disrespect to anyone working in those conditions. My wildland fire experience is bad enough.

My own lyin' eyes are telling me that this is a helluvalot bigger than before the sand-cut and the 'Craw' worked the leak. This BOP flange is about a meter across ,right? A side by comparison of images over time is useful. In the early going there was no leak at the kink and leak #2 was half of a half meter pipe to sea pressure.

From the cut/shear video it's looking pretty likely that the riser kink was holding back more than 400psi from the 'measured' 6 to 8k pressure drop within the BOP, and again from just looking they got more than the pre-cut 20% flow increase estimate in reality. WAG there is little chance the pressure drop is currently that high within the BOP.

A new gamma ray reading in the works? Direct pressure readings? After top-kill/junkshot they must have the info.

Hi PDV

re: your comment Tony Hayward is a geologist. "Vast majority" is not SI (International System of Units).

You are spot-on, but Tony Hayward is no longer just a geologist, of course. He is also a Chief Executive, so SI Units only get used when they support the message! (the message being, "Things are not quite so disasterous and may well improve more within a week.")

Here are some suggested definitions for this 'Non-quantitative speak':

"majority" = >50% of whatever value he was 'advised' is correct based on consensus of the 'most reliable' estimates of the original flow ('reliable' being a rather subjective term in this context since there is no real way to test the estimates)

"vast majority" = any value higher than 'majority', that someone else cannot unequivocally disprove at this time

Just be glad he didn't use the phrase "significant amount of oil"...that would have meant the fix wasn't working at all!

I think we need to introduce a proven scientific formula here. BP's Sock price = Hayward's spin. This formula precisely computes an inverse relationship: The more BPSP decreases the more HBS increases. In another dimension than TOD, this iron law is called The Fuld Law (TFL).*

*Honoring Dickie Fuld, the final (sob) Chairman and CEO of Lehman Bros. TFL was seen in its full glory on September 14, 2008.

that would be VM ± 0.75 * VM (VM = "Vast Majority").

Q: How can you tell when Tony Hayward is lying?

A: His lips move.

Yes, the fins are now clearly visible. Perhaps 50% less escaping flow than when the cap first touched down. That would be consistent with getting 10000bopd from a wellhead flow of around 20000bopd....

If the oil processing trains on the Enterprise are bottlenecked at 15000bopd, then there could be a further 50% reduction in environmental discharge before this processing limit is reached.

Best hopes

Bill

Sorry, I disagree. To me it looks like less than a 22.23% reduction. which would not be consistent with getting 10000bpd from a wellhead flow of around 20000bpd which you have no goddamned idea whether or not that's an order of magnitude off or not. ~:)

All the armchair deadreckoning is hilarious.

200000 bopd has never been seen from any well anywhere in the world. 100000 bopd has been seen from some of the Mega giant fields in the ME when they were first discovered.

20,000 BOPD is a fair enough estimate from what we have seen/are seeing and consistent with what various groups of estimators have come up with. It is certainly not an OoM too low. Of course, it is up to yourself whether you believe this, or anything else for that matter ;)

Oily Bill, I agree and I love TOD because most people don't let political predispositions to get in the way of logic. Except for on the flow rate issue.

The logic is that we should use historical data from past deep water wells in the GOM to set an upper guestament of the possible flow rate, until we actually know what the flow is beyond the shadow of a doubt. All of these fanciful exagerations by people that hate the exploration for hydrocarbons, if true would mean that the deep water GOM could be the next Saudi Arabia and by lettng this information out they would be advertising to the world that the GOM is the best place to drill in the future. The lie of a 70,000 to 120,000 bbls a day producing well in the GOM would attract many more players after the moratorium is dropped and the ones telling that lie would be shooting themselves in the foot.

Now if this well is producing above the average deepwater well in the GOM, you would have to assume that the orifice in the oils flow path is much bigger than other GOM producing wells and that's plausible. The problem with that thought process(in my view) is that if this well was flowing without a major restriction or multiple restrictions it should "sand up". In my limited experience with completions and the production side of GOM wells, they can't flow at high rates very long without gravel pack screens and/or being choked to a rate that does not allow the production sand to plug the well up.

Oil companies don't spend millions of dollars on gravel packs in the GOM because they like to, they have to. SO why would this well be an exception to that? Now if the answer is that BP found a stable formation that is like that of Ghawar in Saudi Arabia, with a high porosity and exceptional permeability, I as a peak oil guy would be very suprised.

In my view(my guess) this well is being choked back by a channels in the nitrogen foam cement job on the annulus of the production casing, by the hanger and damaged seals at the well head of the 9 7/8 casing and by the partiallly closed bops. If this well had a full open flow path it would have killed everyone on that rig and it would have sanded up withing days.

I think 12,000 to 25,000 bbls to day flow rate is a decent range and the entire discussion is pointless until someone proves it otherwise.

I think there is less oil than people believe, because while it visually looks like a huge cylinder of oil/gas is coming out, the center of that cylinder is really the cap. So you have a "ring of oil" that visually looks like a cylinder of oil. Once in a while you can see the cap (only from certain ROVs) so the deepness of the ring is not too large in areas. Just eyeballing it, if you think the volume of the entire column is x, I think the cap is currently occupying ~half the volume.

Note a little more fin = a lot less volume, because the entire cylinder's volume is moving with the square of the radius, and the inner cylinder's volume isn't changing at all.

Does anyone know the radius of the cap and of the fins?

Aard;

I don't mean to be condradictory, but I don't see any change in the oil flow from last night. If fact, the fins look much the same, and if you look closely, you can see that the pressure from the oil/gas/sand mix has already blasted away some of the paint on at least one of the fins. My question is how much longer is that rubber grommet going to last.

As for anything Tony Heyward has to say, the man is a bloody liar.

Pete Deer

You have to realize that last night is part of the 24 hours that BP is using to calculate the flow they put in their press release for today.

Compare the images vs. Friday night and it's clear that improvements are being made.

Admittedly, yesterday I was watching the live feed on CNN which was taken from a higher point of view than the current akamai feed so they are not strictly comparable, but I'd say it's a very definite improvement over 24 hours. Time will tell, I guess.

I think it is hard to tell if there's been significant improvement or not. When I checked the cam a few minutes ago, the veins on the right side of the image were pretty visible, but the veins on the left side were completely obscured. I assume this is the result of currents.

I was watching when they first lowered the cap, and I can't say that the amount leaking now is much less than was leaking then. Originally, the tips of all the veins on the side I could see were visisble. Now I can see more of the vein on the right side and less on the left side.

I wasn't watching last night when people were reporting that it looked better. Were there camera views of both sides then? If not, maybe the oil was just billowing in the direction away from the camera view.

Edit: I'm trying not to be too pessimistic. So long as BP is pumping more through the cap than they increased the flow rate when they cut the riser, then it is an improvement over status quo ante. The big question to me is whether they've reduced the amount leaking into the gulf to a level that is not catastrophic to the GOM, and it isn't clear to me they have.

This is a great post. A bit OT, but I love the blue color on the site.

There's no bp tech info until 9 am CDT.

I would like to see live or recorded video streams of people working on different aspects of the oil indutry. It's a great way to learn. Also, other industries as well.

Perhaps a respect for "blue collar" jobs would come into being again.

The diagrams look to me like a race to the top and that every time, gas is the winner. Correct me if I am wrong.

Again, I am grateful for this site.

I unintentionally got someone hooked on the live feed by posting pictures from bp of the LMRP on a cork board. I do volunteer computer tech and my end users are mainly teens.

Yes, containing gas pressure and gas itself is the biggest challenge. In the production tubing the gas is most likely dissolved in oil but will bubble out as pressure drops towards surface. Recall it was a gas explosion that destroyed rig.

they put up the full Hayward interview at http://www.deepwaterbp.com

http://www.youtube.com/watch?v=3b6J7LRUTFY

That's all the Hayward you need to know right there.

"We had too many people that were working to save the world"

"...our primary purpose in life is to create value for our shareholders..."

"...our primary purpose in life is to create ___value____ for our shareholders..."

I wish all CEOs would remember this! Wouldn't be in this economic fix if they had.

The goal of many executives is short term value. Quarterly reports and today's stock price frequently determine job security. Long term value is for investors and today's stock market has become a day-trader's paradise. I haven't even mentioned short sellers. BTW, I think Hayward is quite secure. Who would want to be the face of this dog's breakfast?

last post previous thread asked about what ent ROV 2 was looking at. same question, here's the capture:

That's one of the information/diagnostic screen displays from the ROV control room. The pilot can toggle through a variety of screens to look at things like hydraulic performance, adjustments, limits and alarms, etc. Their setup is such that that screen is getting broadcast at the moment. Somebody needs to switch the selected video channel to get the right one streaming out. But they may be on deck right now and it's a moot point.

Yes, that's obvious - I meant what are the particulars. ie, i see the trash pump is running ... this is the oil pressure in the pump?

thanks

Euan, Thank you for a nice explanation of the basic geology

Regarding overpressure in the resrvoir, you say that the "The rocks above can then exert some pressure on the water." Is the correct picture here that the overlying rock is elastic and that the reservoir pressure is driven by some strain in the rock? If that is the main driver, then the reservoir pressure should drop as the strain relaxes.

If the well remains uncontrolled, one can expect that the reservoir pressure would eventually fall low enough that the flow from the well would stop by itself.

Is there any information from geologic survey data or from similar wells or from any other sources as to when this might happen. Clearly, this must be a rough estimate given the uncertainties in the actual flow rate from the well. In particular, is it possible that this might happen before the relief wells are ready. Or is it impossible to make such an estimate because so little is known about the details of the reservoir?

Correct, pressure decline occurs in all producing reservoirs. Oil gushes out on its own to start with, then either water needs to be injected to maintain pressure, or you need to pump it out.

Impossible to say when this will stop of its own accord without knowing size of reservoir, flow rates and actual pressures. Probably years.

Would you compare an overpressured HC reservoir to an artesian water well, For us non-engineers? An artesian water well will flow, sometimes spectacularly and over time the pressure usually declines. The water producing formation is capped by an impermeable layer. Water wells normally don't have enough pressure to push the water to the surface.

Not exactly. If you have positive pressure in ground water that makes it flow to surface that will normally be derived from a hydrostatic head - the layer of permeable rock stretching up dip / up hill to some nearby mountains.

But the need to have a top seal to confine that pressure is same principal as geological over pressure.

Oil can be saturated, over or under saturated with respect to gas. Assuming this has both oil and gas in the same reservoir (not proven) it would mean over saturation, which means that with oil production, you have some gas cap expansion driving the reservoir. In this case, you most likely have a significant water drive as well.

Rockman's comments above puts several of the problems of drilling into great perspective, but there is yet one more complication with drilling I haven't seen fleshed out in the technical threads, and that is a situation I keep hearing about with some of these near salt and sub salt plays in the deep offshore -- where an overpressured zone overlies a less overpressured zone. The sands in these zones are bracketed by "suitcase shales". What this means is, to drill through to deeper zones, you would have to engineer a well with additional strings of casing. The first exploration well on a prospect is often over engineered with respect to the size and number of strings of casing -- subsequent wells have the advantage of the driller's knowledge of pore pressure. McMoRan gave their Davy Jones discovery presentation earlier this year about drilling deep (30,000') for a subsalt prospect near the Louisiana coast (The BP blowout well is reportedly not a true "sub-salt play" but there is salt in the area) but with these deep wells, you can find reversals in pressure gradients.

This was one of the exhibits presented this last February in the McMoRan discussion.

It's a stylized well log, with the sand in yellow, the resistivity on the right side, and the shales (mudrock) showing a trend indicating pressure ramps, or seals above a different pressure zone. In short, it's an engineering nightmare to get there and to control the various zones of interest. The McMoRan discovery well also encountered extreme heat(440degF), but that's another discussion.

Euan

Thank you for the simple explanation. Love the charts.

Question: When there is a large earthquake either on land or sea, why don't we see oil leaks of this magnitude that go on for long periods of time?

As a general (but not fixed) rule, oil and gas fields tend not to occur in areas prone to earthquakes.

But top seal failure does occur, and its likely that major natural spills are quite common - like they may happen every few thousand to hundreds of thousands of years. But even then, in nature, the oil does not have a steel pipe to escape to surface, and will spread out through fractures in the rocks in the sub-surface.

The Los Angeles basin has oil fields, earthquakes, and a famous natural seep, La Brea tar pits. Oil doesn't flow up a fault because the lithostatic pressure (weight of the rock overburden) holds the fault shut; it isn't an open crack.

Although, I am still adamant that BP's engineers are somewhat incompetent. I have to accede the fact that the oil/NG leakage seems to have decreased sharply (like someone said the fins are now clearly visible). My only question is: Can they close off the other two valves and still maintain equalized pressure in the BOP and connector? Your thoughts?

Are the top-vents still open?

Definitely more fin this morning, and sometimes the casing is visible as well. As long as enough is billowing to make obscuring clouds, it seems like a lot, but this is MUCH less than before, IMHO.

I'd go so far as to say they have the majority, though perhaps not a vast majority.

Anyone have a still of 24 hours ago to compare to day's flow? As I layman, yes I can occasionally see "the fins" but as a resident of coastal Louisiana it sure looks like hell on earth still to me.

Hmmmm... some improvement. Not as much as I hoped.

Edit: But note comments downthread -- some of the valves on top of the cap might have been closed, forcing more oil out from under the rim.

Your ignorance is showing badly.

This effort is not just BP's engineers. It is the top engineering talent in the world wide oil industry plus people from several other industries and national institutions like the NSF helping out. This includes Steven Chu, the current Secretary of Energy.

Here is an article regarding Dr. Chu:

http://en.wikipedia.org/wiki/Steven_Chu

If you have better please let BP and Mr. Obama know.

Hey, Speaker-to-Seafood, your temper is showing badly. Dial it down.

It should be obvious to all, by now, that the existing ROV technology is poorly suited to the tasks at hand. The only sensing modalities are vision and perhaps sonar. The only actuation modalities for many motors appear to be on-off.

We need better sensing modalites (touch, proprioception, chemoctactile, flow) and better actuation modalities (proportional control with force feedback) as a start. We need tools at hand to unbolt flanges at depth. We need ultrasonic drills and/or water jet cutters that can go through steel like a hot knife through butter. All of these technologies exist, but BP didn't have them on hand. Their negligence, their bad. But hey, they worked cheap and fast, right? Remember the other point of that triangle?

All the top engineering talent in the world takes years to get this kind of stuff ready.

Right - the only sensing modalities are sonar and sight.

NOT.

We have already seen X-Ray and Gamma Ray imaging used to probe the interior of the BOP.

There is a massive amount of instrumentation being mustered to study this spill, and even more available if needed.

http://www.sciencedaily.com/releases/2010/05/100528211158.htm

http://www.link-quest.com/html/deepwater-current.pdf

Water jet cutters for undersea applications are already in use in the North Sea.

http://www.ant-ag.com/offshore.html

I was talking about routine sensing complement of the ROVs, not the extra instrumentation that has to hauled into place by the ROVs.

The water jets you mentioned (http://www.ant-ag.com/offshore.html) are for use only to 600 meters depth. The Macondo wellhead is at 1500 meters depth.

Avonaltendorf's mention of stereo vision is good.

Separately, having a riser pipe extending a mile from the wellhead to the drilling platform is just mind-dead. Ultimately we need full drilling capability (robotic and teleoperated) sitting in a submersible barge which rests on the mud at the wellhead. That will take a long time to build, but the rising cost of oil may justify the time and cost.

Ever see The Abyss?

http://www.imdb.com/title/tt0096754/

Wow you have some wild ideas. If I was a regulator there is no way I'd approve a teleoperated drilling operation at the depth of one mile. Something goes wrong and you are completely without the ability to do anything about it. And a submersible barge? At the depth of one mile? Do you realize how dangerous that would be?

As far as dragging a raft of sensors around extreme depths, that isn't good for the sensors at all. Wear and tear etc. Much better to just bring what you need.

Sorry about the jet cutter. Still I bet that they could rustle something up if need be. It wouldn't have worked in this case anyway because of the presence of the drill pipe in the riser. Jet cutter nozzles have to be right up against what they are cutting.

Better sensing and control are common in other areas, and could be in ROVs, too. Should be a priority.

At a minimum 3D stereoscopic VR for the crew. Blundering around in 2D flat video without depth perception is inexcusably silly.

Do these pressure factors affect how any relief well will work?

And are there safety issues that need to be addressed, for example at the point that the relief well makes it to the "target" of the wild well?

I ask these questions based on Rockman's statement yesterday that the riskiest moment for any relief well is the point at which it reaches the wild well - when there's a risk due to the relief well taking all the "kick" of the wild well.

Here's the part of Rockman's comment that pertains:

Link for Rockman's comment: http://www.theoildrum.com/node/6564#comment-641275

Thanks!

See above you stinkin' nobody.

Will do. Sorry, I'm in a rush this am... I accept your terminology. ;)

Rockman's answer is here. Posted actually while I was working on my question:

http://europe.theoildrum.com/node/6526#comment-642300

Blessings upon you, Rockman! I so appreciate your expertise!

It's prolly about time to promote you from noob to freshman.

Congratulations.

Here is yer homework. There will be a pop quiz on Tues.

http://www.theoildrum.com/node/4172

http://www.theoildrum.com/node/5582

Thank god I have Monday off! I will study as directed. I am pleased to have passed the initial hazing. ;)

TheraP...just some advice because I believe you will stick it out here while others will disappear after the disaster has passed. All of us here at TOD have gotten upset with others at one point or we have ribbed others at another point or just learn to ignore some others at some point. It can be a bit of hazing, but this community works....warts and all. The technical folks are highly tolerant of the less technical and the less technical put up with the arrogance of the more technical (i.e. ROCKMAN, westexas...just kidding).

It is good for the non-tech folks to wander over to the Drumbeat or the occasional Campfire to get out of the "fire" of the tech articles.

Hope you enjoy your time here...wait for Leanan to come back and you will not be sorry. She runs the Drumbeats, but is away at the moment.

I am honored. Truly. Thanks for your kind advice.

I'm doing my best to stretch my brain beyond it's normal boundaries. I actually explained a lot that I've learned here to a bio-engineer this morning and she was very impressed. You folks do a super job of providing an education. As I've said before this is an outstanding community. I knew the ribbing was a good sign. :)

Sorry I've been busy today. I salute all of you!

BP Video on Relief Wells from June 2nd, and at second 23 there is a casing schematic of all the wells. I've seen this posted elsewhere but it was too small to see the numbers.

Estimating from the figure, and vertical depths, it appears like 16" casing is set at 12,000', 13 5/8" set at 13,000' and then a 11 7/8" liner at 15,000' presumably tied back into the 13 5/8". There might be an error in this figure, or the Halliburton schematic because the latter shows the original well as also having the 11 7/8" liner and the June 2 video doesn't show that. Pretty much the exact same casing job as first time except we don't know the weights and grades or if the week spot may be in the liner hangers. It looks like they plan to intercept the LW below the 9 7/8" liner which is at 17,168'. Full reservoir pressure should be expected at that point. Is this casing string adequate to do the job?

With all the focus on the webcams at the wellhead it would be nice to get something similar for the relief wells. How about a cam that monitors the drilling mud flows along with pump pressures, strokes, etc. I mean the whole world knows there is a lot of oil down there so it's not like a confidentiality thing. I'd like to see them post the morning drilling reports just so all us armchair engineers can see what is really going on.

Very impressive. Why isn't the media presenting interviews of these guys? Where are the interviews of the people working to cap it? Coast Guard, BP engineers, contract employees, etc. Please post more links to the videos of the teams working to plug this thing. Thanks.

It was good to see the "Boots & Coots" logo on the Intersection Team Leader's shirt. They really are the best in the business at this.

Great video. The dude hasn't missed in 40 RW's attempted. That's the guy I want in command.

As to why they can't be in front of the media first they are either under NDA, if they are contractors, or forbidden if they are employees. If you want to hear what BP has to say you can see their SEC filings.

In that vein they are releasing daily 6-K's. You can find and read these on the SEC EDGAR site.

There are some interesting recent (last few days) items including a press release restating the BP commitment to their efforts by the Chairman and CEO; how they are funding the barrier island shore protection for LA; a Moody's downgrade of BP's ratings; and finally this:

I will be very interested to see what they are saying tomorrow.

Wouldn't the RW be tapping into lower pressures as the leaking well is still releasing pressure too? Two RW should reduce the pressure between them by half. Maybe not quite as dangerous pressures as the initial tap.

I hope you guys are right in that there is an improvement in the amount of oil gushing out to the sea.

Frankly, I don't see much improvement. But in this case, I would really, really like to be wrong.

But in the meantime, I think I will sharpen my pitchfork and check on my supply of torches.

:-)

The problem is BP is lying. The Coast Guard is simply repeating their lies. There is no independent source of information (other than the armchair analysis I find here. Thank you to everyone with the skills who is contributing, and to our hosts (you can contribute to keep the site going somewhere up top).

Fortunately, down here in Louisiana, we have learned the hard way that all of the people in positions of authority are powerless to help and will lie to cover that fact. That doesn't make it easier. It makes it harder.

God Bless Billy Nungesser, president of Plaquemines Parish (county) Louisiana: "A small tropical storm could push all that oil into the marshes and destroy coastal Louisiana. If that happens, may God help the people who stood in our way."

kind of think they'll keep the gush large as they slowly close vents and add the Q4000 system - to be safe

NTL, comparing to earlier screenshots - the gush is, in fact, less

If the first relief well works and succeeds in killing the leak, what will they do with the second relief well? Abandon it, or drill down to the formation and convert it to a production well?

Just a guess aardy but I would suspend the second well so I might be able to utilize it later to develop the field. But, needless to say, "later" will be years down the road.

BP is facing a new PR battle now that oil is washing up in other states like Alabama and Florida. Alabama mayors not too happy...see below.

http://www.cnn.com/2010/US/06/05/gulf.oil.disaster.mayors/index.html?hpt=T2

BP official grilled by frustrated mayors at news conference

What cracks me up in this video is when Fryar says, "I've vacationed on these beaches for 10 years. I grew up here." Trying to show his empathy for the people that actually live and work there. Glad he can just "vacation" and then leave. Some folks have to live with it all the time. I really wish they would not have BP make any more public statements. At least let the local officials get debriefed in private and let them talk.

If 10,000 barrels/day are captured now, and if that's the 'vast majority' of the total flow, as BP CEO Tony Hayward claims, then the remaining flow would be less than 5,000 barrels/day. That's less than 10 litres/second, or less than one bucket of oil per second.

Take a look at the livestream: http://bit.ly/SkROV2. To me, it is totally improbable that this would be less than one bucket of oil per second.

Remember there would be about 3x that much gas as well. I won't make any attempts to estimate leakage flow rates, but I imagine it doesn't take much to make a pretty good show.

Thx for that. I wouldn't put a number to the flow rate either, but I am quite sure that it's a lot more than 1 bucket of oil and a couple of buckets of gas per second. What's the diameter of that light blue dome we're seeing (is it the BOP)?

I've been watching this more carefully than I care to admit. There is clearly more effluent visible now than yesterday. Yesterday I could clearly see the body of the cap; not now. However,I believe that the view shown to us does NOT show what's coming out of the valves; it's too low down and close to the cap.

There would seem to be three possible reasons for this increase:

1. BP is receiving less oil up top due to system problems, possibly temporary.

2. The well is putting out more oil.

3. BP has closed some/all of the valves, and the system is not capable of handling the extra volume.

My guess is 3. Any opinions?

Seems to be popular to speculate about the flow and the leak. I think your point 3 may have merit - if they shut off all the valves then the only leak is now from the base of the cap. Remember they need to allow some oil to leak so at to not suck seawater into the system which might lead to formation of gas hydrate / clathrate.

When is the 'flow rate technical group' established by the government expected to come up with better numbers? Sofar, only a 'preliminary' estimate, described as an estimate of the lower limit by 2 group members, of 12,000 - 19,000 barrels/day, but that's more than a week old (27 May), before sawing off the pipe!

I noticed this as well, about one hour ago, shortly after I posted the updated BP numbers.

On the first day, they shut down the system for three hours, but never said why, so this could be a system shutdown while they tend to some issues. Maintenance, perhaps?

They've stated that the output can vary over time, so it's possible that the output has increased.

Let's see what happens in a couple of hours.

I hope they shut the valves -- I haven't seen a top-side shot in a day or more.

I think the answer is (4) -- they're getting a lot, and are going slowing in the ramp-up now.

You could see the body in the lower shot this morning. It might vary from time to time, so I can't say for sure how it's doing overall, but at least my peek today it looked much better than a peek yesterday.

The latest update from BP's site:

Subsea operational update:

• On June 5, a total of 10,500 barrels of oil was collected and 22 million standards cubic feet of natural gas was flared.

• Optimization continues and improvement in oil collection is expected over the next few days.

June 6, 2010 9:00 am CDT / 3:00 pm BST

http://www.bp.com/extendedsectiongenericarticle.do?categoryId=40&content...

10,500 bbl/day oil x 6MMBtu/bbl = 63BB Btu oil/day

22MM scf gas/day x 1050 Btu/scf = 23.1BB Btu gas/day

Gas/oil ratio in Btu terms = 23.1/63 = 0.37

So what's the G/O ratio in standard terms, because the Btu ratio sure is lower than what's been bandied about upthread?

It's a volume calc - not a BTU calc. The volumes impact production and how you go about doing it.

From Wikipedia

When oil is brought to surface conditions it is usual for some natural gas to come out of solution. The gas/oil ratio (GOR) is the ratio of the volume of gas that comes out of solution, to the volume of oil at standard conditions.

A point to check is whether the volume of oil is measured before or after the gas comes out of solution, since the oil volume will shrink when the gas comes out.

In fact gas dissolution and oil volume shrinkage will happen at many stages during the path of the hydrocarbon stream from reservoir through the wellbore and processing plant to export. For light oils and rich gas condensates the ultimate GOR of export streams is strongly influenced by the efficiency with which the processing plant strips liquids from the gas phase. Reported GORs may be calculated from export volumes which may not be at standard conditions.

The GOR is usually measured in cubic feet of gas per barrel of oil or condensate.

If the GOR is greater than 10,000 cf/bbl, then the field is usually described as a gas well. If less than 10,000, then the field is generally described as an oil well.

Initial: 3000 scf/bbl

June 4: 2580 scf/bbl (15.7 MM scf, 6077 bbl)

June 5: 2095 scf/bbl (22 MM scf, 10500 bbl)

Is the declining gas content a trend or a fluctuation?

If it's a trend, what does it mean?

It wouldn't surprise me that it is a trend, but I would expect a lot of "noise" with respect to these numbers, as when a "slug" of gas comes up, it will expand enough to push more oil out the partial seal at the base of the cap, and there may be a preference of gas to go up the riser -- or equally, the other way around for nearly the same reasons (gas slug blowing out the base of the riser).

This report is dated 12 August 1999. After reading it I was pretty depressed. Rather than get into the details I'll just post the link.

www.mms.gov/tarprojects/311/311AA.pdf

I just skimmed it, hope to read it in more detail later. What depressed you about it? The complexity of the situation, the fact that the technology they recommended in preparation for such an event has never been manufactured (to my knowledge, don't really know), or what?

Oh, by the way--I found this statement in the report ironic:

There is very little blowout experience in deepwater from which to draw when

evaluating countermeasures.

I guess they have their data now.

The overlooked aspect of the graphics is that at a break in the well in the third graphic at -5000 ft that coincides with the sea floor the friction of the water interacting with the blow out of the well decreases the pressure of the oil in a rapid fashion until it matches the pressure of the sea water. From that point forward the density of the oil in relation to the density of the sea water controls the potential pressure of the oil that attempts to float in the water. In effect the energy of the oil is lost to the water and the primary force on the water is whatever buoyancy the oil maintains relative to the water.

There is a relationship established yet unknown that controls the volume of water needed to equalize the pressure of the well to the pressure at the sea bed.

If that volume of water is calculated and the oil water mix is captured in a screened area in the shape of a pipe of sufficient capacity, then the oil water mix could be passively separated within the pipe by gravitational forces, especially if the pipe is placed as a barrier upon which the oil can rest as it moves. My guess is that a pipe of 20' diameter and 1 mile in length would do the job.

The pipe or screen would need to be able to separate the gas before entering the tube. The tube would need to be neutrally buoyant and of sufficient strength to withstand currents, temps and pressures at -5000 ft.

My contribution to such a device is located here: http://www.theoildrum.com/node/6566/642064

I think in the last engineering video by the BP guy (May31), in the latter part of the video he showed a pic of the construction on a "jacket" with very thick walls that might go around the cap to help with the total capture. I'd like to see more on this, and hope this necessary "partial seal" is just a temporary issue.

The difference in their idea and mine is that I use passive separation of the oil from the water and storage of the oil in a sub-sea manner. This makes operation of the device during hurricanes and storms possible and storage at a depth below the zone of influence of the hurricane.

I do appreciate your input as you have brought up an important aspect of the problem. I was hoping for more constructive criticism from others in addition to your helpful comment.

Generally I like the idea, the transition to the sock might be tricky because of rapid expansion, so a transition structure of some kind might be necessary. Then again the open bottom of the sock might be just fine. Or the bottom 100' or so would have to be extra heavy or steel. It also might help to extend the broken pipe farther up the column.

Very reliable means of removing gas from the sock needed. Should be possible to have redundant pipes/valves to safe areas.

I just skimmed your orig post, I don't get the jet pump part. I don't get all the fabric stuff. I think the sock might be big enough that stratification might happen at a rate oil/gas/etc could be pumped out at different heights as needed.

BP, Prior to Gulf Accident, Said Measuring Oil Flow Was ‘Critical’ to Effective Response

http://www.propublica.org/ion/blog/item/bp-documents-prior-to-accident-s...

Just want to say it's sad that BP/"the powers that be" will not let us see what's happening top-side. Hopefully at some point the efforts of those risking all to manage this disaster will be recognized.

I certainly want to thank all TOD contributors and the ROV crews whose feeds I watch daily, who I can only assume make a difficult job look easy.

Thanks to everyone!

How about a ROV camera shot that is about 30 feet back off the cap so we can get a better estimate of how large the effluent is still leaking into the ocean. Not too many of those types of shots. Lots of close ups, but nothing to give you a good feel of the total effluent. Is this by design?

not enough light for a 30 ft off shot. everything you see is illuminated by ROV lighting.

There were some really nice perspective shots some days back when two ROVs were working around the kink and the third was up above and off to the side providing video. The two close in provided the light for the scene and it provided a good overview of the situation.

How about 2 ROVs lighting behind the plume, one at the source and one 30' up the plume and then a 3rd ROV taking the camera shot 30' away. The specifics are trivial. I just have not seen very many wider angle shots, they are all close ups. Heck, even 10' above the cap would be quite interesting to me. How about a ROV that follows the plume from the cap and then all the way to the surface?

You can light up the plume all you want, but the 30' of water between the plume and the camera absorbs and scatters a *lot* of light.

Taking clear photos of anything underwater at more than 10' distance is difficult; at 30' it's damn near impossible.

OK, holy jeezus, give me 15' then. I just don't want a shot 3' from the fricken' source. Pan the camera up a bit once in awhile.

Personally, I'd prefer that all the ROV's stay deployed on stopping the thing....

I think all of the ROVs are equipped with a sector scan sonar. If so, a fairly accurate estimate of flow can be made at zero impact to current operations. Record sonar images from all three ROVs stationed at the well, the mean and limits of the diameter of the plume can be made directly. Accuracy will be good because of the nifty steel cylinder reference (cap 4). The density of the plume can be measured by both the distortions in the shape of the cylinder and the contrast between the brightness of the water/plume/steel interfaces. There are multiple independent groups that could easily do this analysis (Navy, academia and industry). No new research or technology required. Probably would take a day for the first rough cut. Then another year for all of the papers exploring the problem in excruciating detail :).

As far as lying, its is WITHOUT QUESTION not in BPs interest to lie or deliberately mislead about the flow rate. Remember there is a good decade of lawsuits to come and BPs attorneys are making every effort to prepare the ground. Lying is the absolute best way to screw yourself. BP has been carefully sticking to the essence of "No comment" unless they are sure of the truth and accuracy of the answer. Mistakes and misstatements are mercilessly attacked in court regardless of the innocent intent. Attempts to assuage public fears could cost the shareholders billions later. Always plead the fifth!

It is WITHOUT QUESTION in BP's interest to lie, conceal, and misrepresent every detail of the Macondo disaster including flow rates past, present and future. Shredding documents and data happened in the first 24 hrs after blowout. No proof, no guilt.

Been reading too many novels have we? Do not judge everybody by what government officials or you might do.

Not true. For a civil action the standard is "preponderance of evidence", IOW 51% proof. And even that is a jury's opinion. Lawyers like to lead jurors to infer what was on those shredded documents even though the jury is supposed to disregard them. Lying to hide culpability only helps if it prevents a court action. There is going to be so much discovery by so many parties that BP's lawyers should be disbarred for incompetence if they allow BP to say anything that can be proven a lie.

Hi avonaltendorf,

I'm not picking on you, just using your comment as an example. So please, don't take it personally.

It is the custom on TOD to back up critical statements presented as fact with proof. This usually means providing a link to a document which substantiates the fact presented in the comment. Links to MSM (main stream media) are typically discouraged as they are often incorrect, (that's why we are here, right?) That said, they are better than fringe blogs ;-)

Stating BP shredded documents and data in the first 24 hours after the blowout is an extremely serious charge that could land people in jail. Not you, the shredders :-) Although, technically, I suppose you could be accused of libel if certain legal standards were met. But I digress.

Everyone who contributes to TOD, either in the form of an article or a comment about an article, sets the tone for what TOD is all about. I'm not a TOD volunteer or even a long term member (just about 2 years), but I think I won't get kicked in the butt for saying that one of TOD's core strengths is its ability to focus on facts and not fall into the trap of discussions based on assumptions.